Search

Back

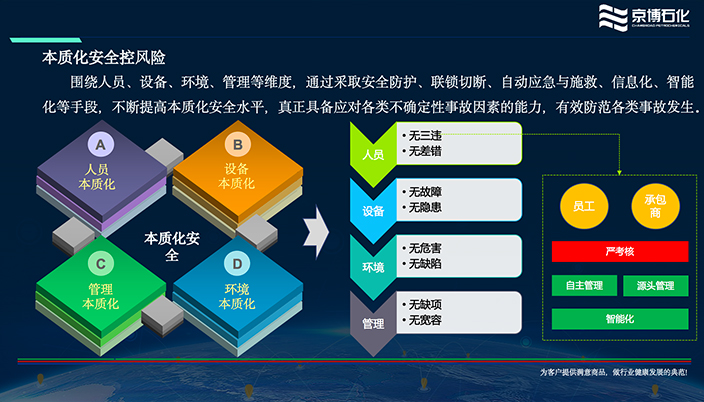

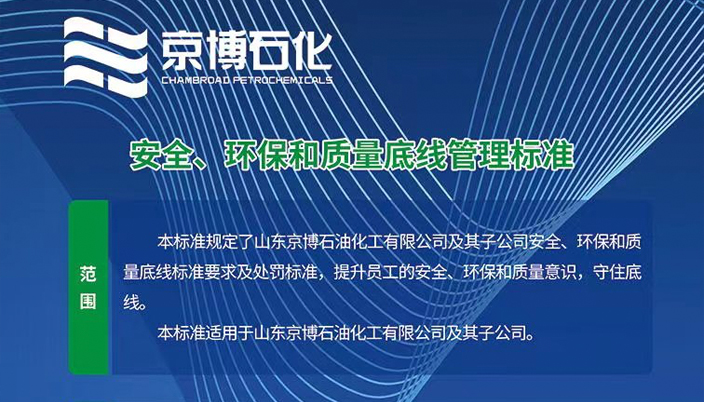

Objectives/Policy/Management

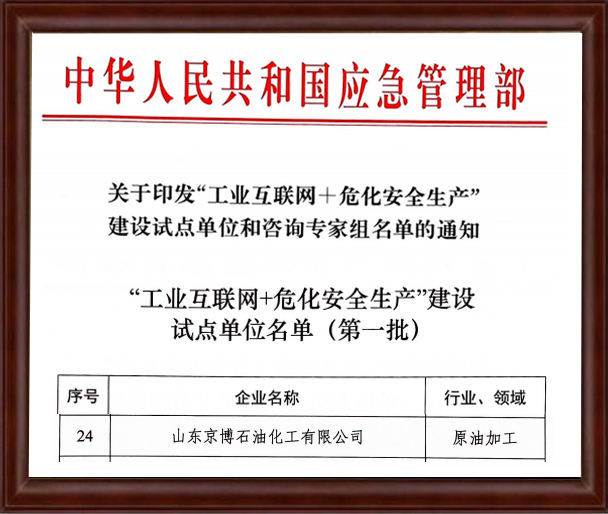

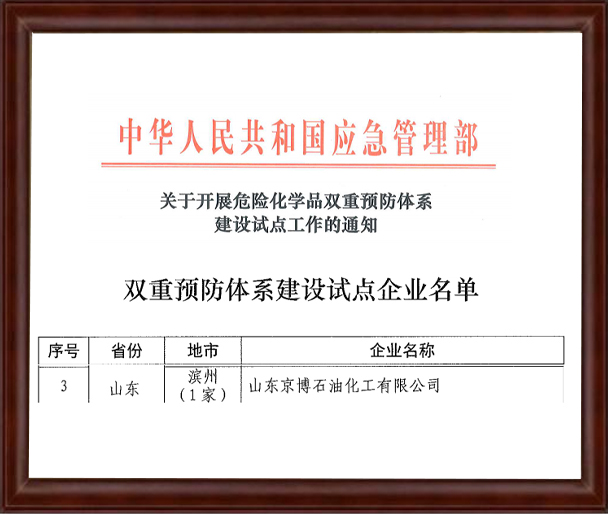

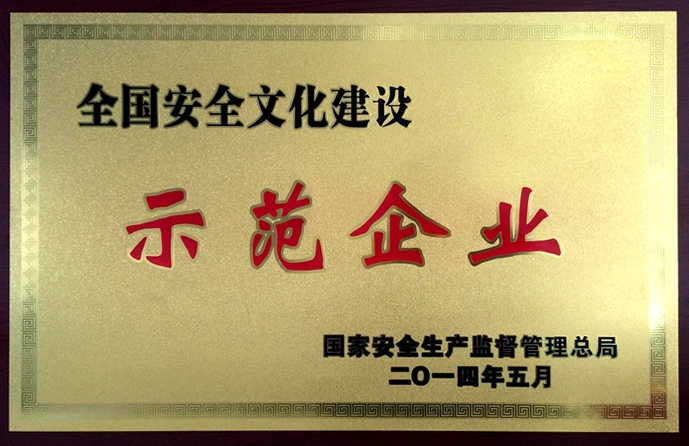

Safety-related awards and honors

Results of Safety Management